Pulses processing, Seed Processing and Color Sorting Machines

Seed Cleaning, Seed Polishing, Gravity Separator Machine

-

Visit us in AGRITECHNICA FAIR -

Website online -

Our first installation for our new establishment in Bulgaria -

Our new modern factory at your service -

We carried out our Pulses Processing Plant installation to Egypt. -

Gaziantep installation of packaging machines and equipment company was completed. -

We carried out our installation in Kenya -

DMA 2015 - 6th International Milling Machinery Exhibition -

Mixing Bird Feed installation Plant was completed in Bulgaria -

Screening and Sorting Plant in Egypt -

AKY Technology sent a Dreied Beans Cleaning and and Processing Plant to Bulgaria. -

AKY Technology has delivered Pulses Cleaning and and Processing Plant to Mersin Company -

New Generation Color Sorting Machine ( Foto Sorter ) -

Lentil Screening Plant -

Watermelon Seed Cleaning Plant -

GPC Celebrates World Pulse Day -

Support for economic investments based on agriculture. -

SEED CLEANING PLANT IN KIRSEHIR, TURKEY -

Third plant investment in one year by Djilisoy in Bulgaria

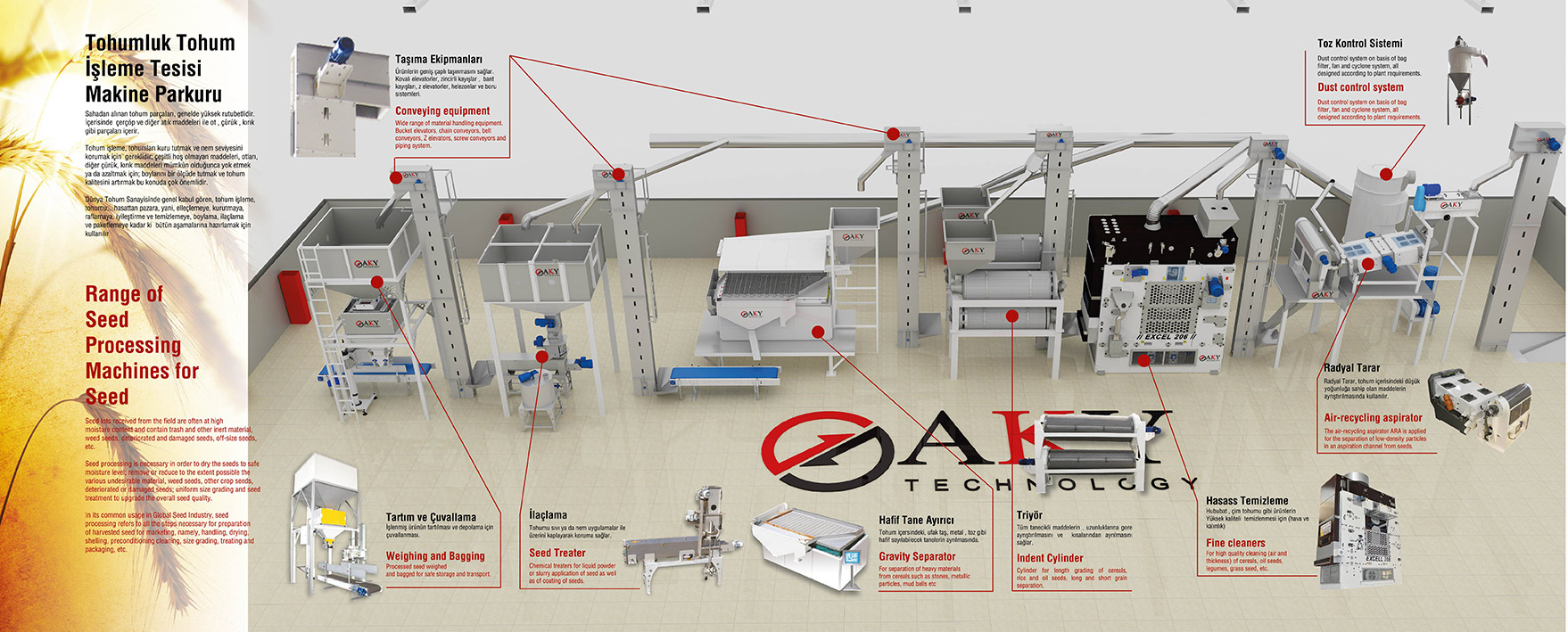

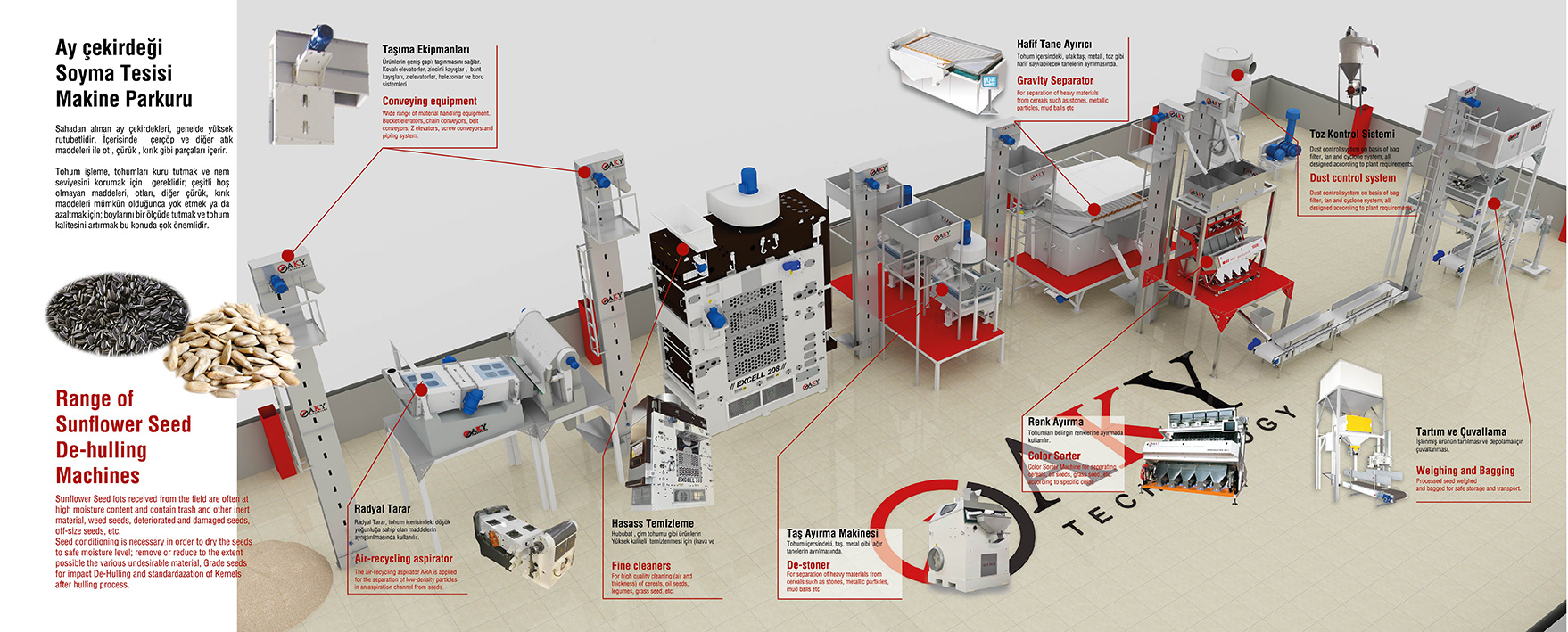

AKY Technology manufactures technological systems that manages the process from harvest to packaging, also a spare part supplier and installer.

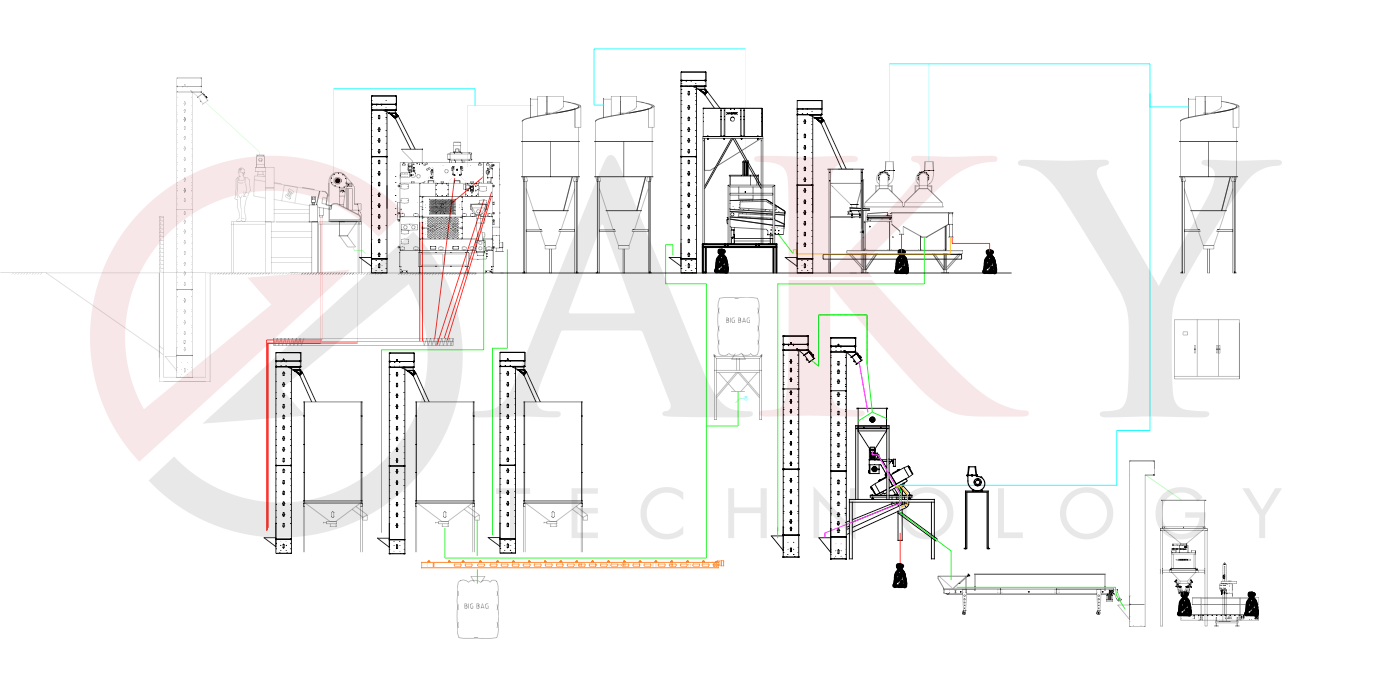

Screening Plant Projects

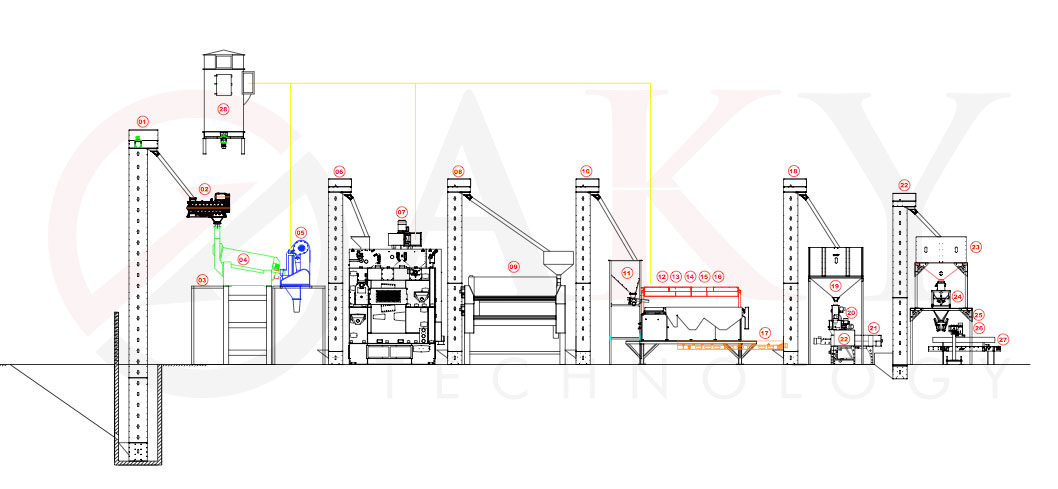

Seed Cleaning Plant

A Seed processing plant splits the natural product which comes from fields from the lean harvest. It also calibrates the product with desired sizes and processes 10 tons/hour input product with %95-97 purity. Whereby using Fotosorter (Color-sorter) output purity can reach up to %99.9.

With de-awner machine, awns of barleys are peeled so that seeds germinate easily. With pre-cleaning system (vibro separator and air re-cycling aspirator) dust and crude grains are taken out from the flowing system. Excell Cleaners are used for calibrating and super-fine cleaning of the product with the desired quality and sizes. Oats, gleanings inside product are taken out with the help of indent cylinders. Polishing Machines are used at the end of seed processing line. It is used for treating the seeds with homorganic liquid. So that seed is protected from insects and harmful microorganism. After all the cleaning and sorting process, the product is packed with PLC controlled bagging machine with the desired amount.

With this seed processing plant, you can certificate your seeds.

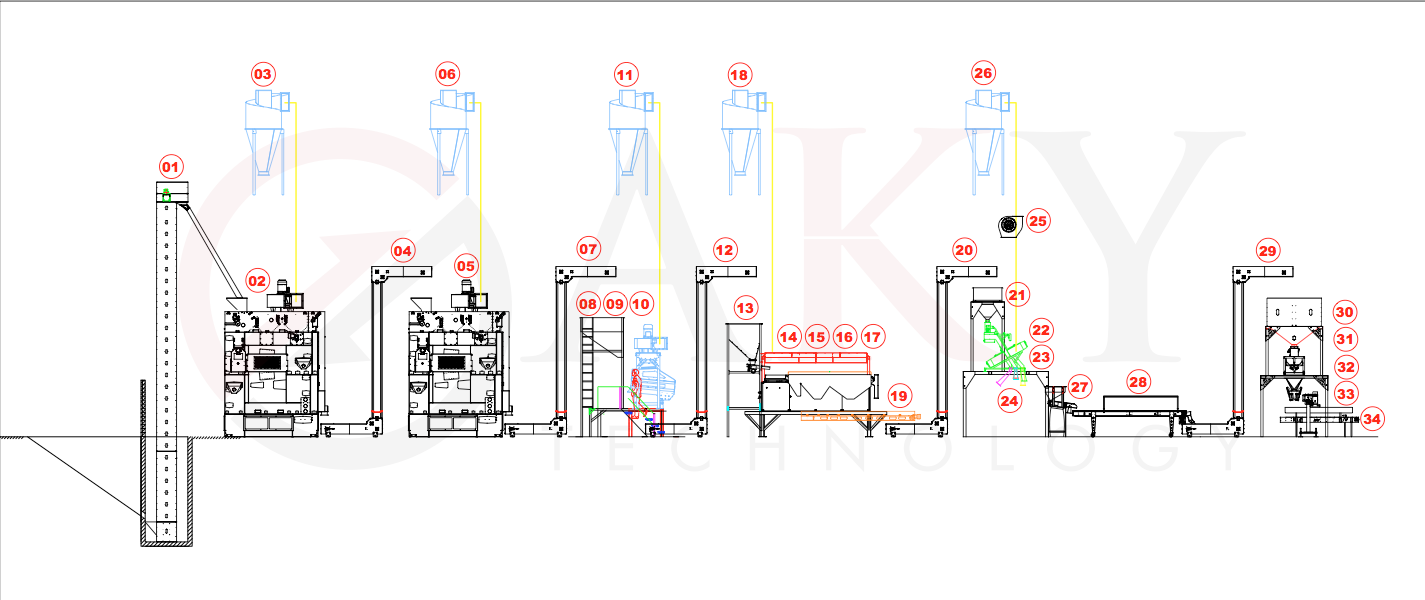

Pulses Processing Plant

Pulses Processing Plant

In Pulses processing plant, unprocessed products passes from screening machines for screening raw and broken products and for calibrating process. Later, products could be bagged as per request in bagging machine

The aim of this plant is; getting maximum value of pure products with high quality technological machines.

In Pulses Processing Plant;

1) Sensitive Cleaning Machine; screens the dust, corp, chaff, etc. from the product and finishes the pre-celaning process. Later; for sorting the high density things, product enters to the stone separator.

2) Stone Separator is mostly for sorting impurities like; stone, glass, dust, etc. Later the product enters to the Gravity Separator for separating light products.

3) Gravity Machine is used for separating the light materials from the product. This machine finalize the cleaning process. On the next step; product passes to the color sorting machine.

4) Color sorting machine is mostly used to separate and calibrate the processed product to their color and type. Thus; the products purity level increases to %99,8.

5) Scale and Bagging Machine is used to weighing and bagging the processed products with optional

Sunflower Processing Plant

Bean Plant

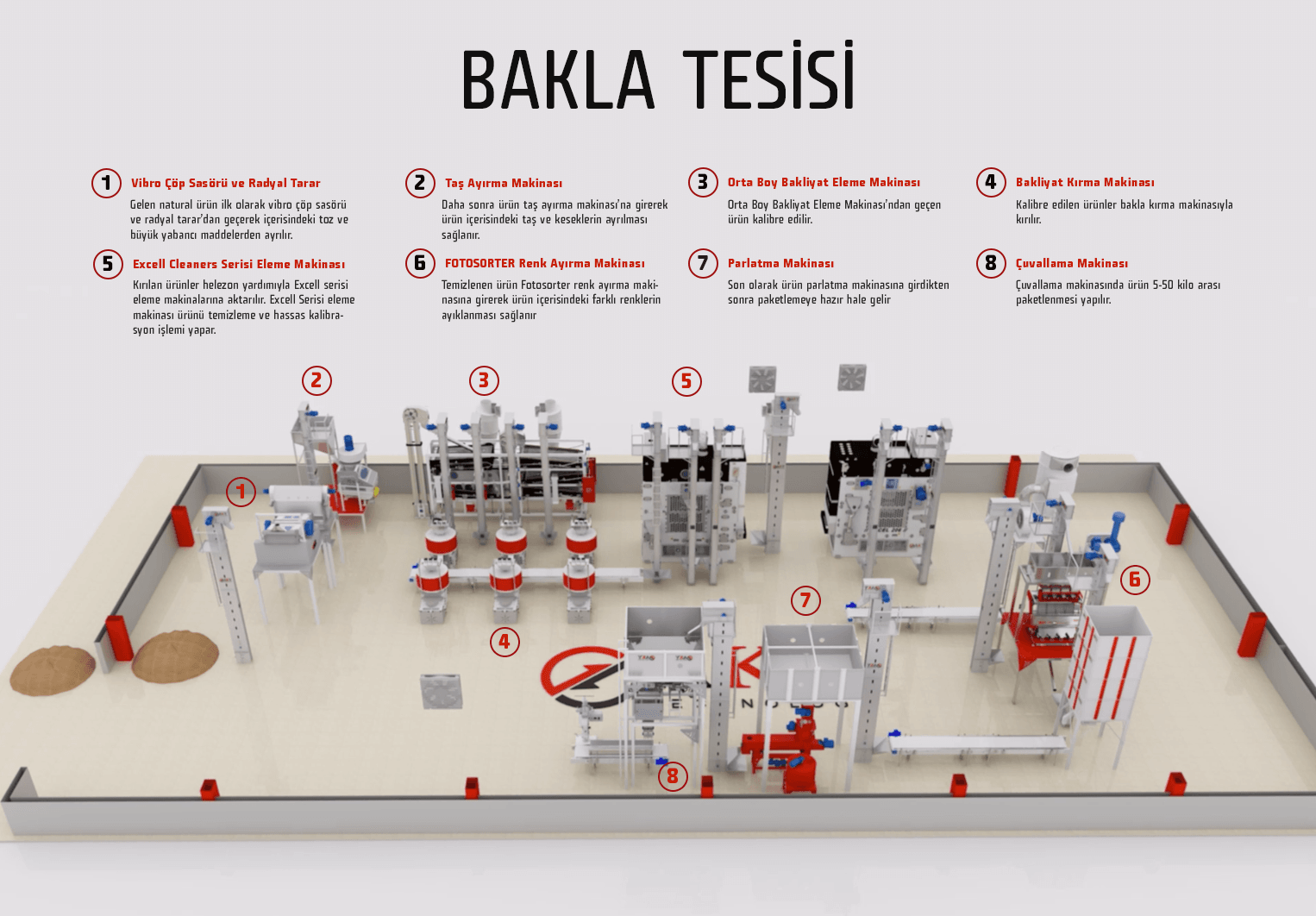

Fava Bean Plant

The Natural product which enters to the fava bean plant firstly passes from vibro air aspirator for being cleaned from dust and impurity. Later on, the product enters to the stone separator machine. On the other process the medium size screening machine calibrates the product, and the calibrated product splits in the Fava Bean Splitting Machine. Excell Series used to sensitive calibrating and cleaning. Cleaned product enters to the Fotosorter Color Sorting Machine. Finally product enters to the liquid treatment machine and later to the bagging machine for filling between 5-50 Kg’s bags.